Valley Tech Systems, Inc., has designed an Active Nozzle Propulsion System as a screw-in upgrade for U.S. Army rockets that can significantly increase range and maneuverability. Specifically, it can increase lethal range by more than 67 percent and decrease turning radius by approximately 70 percent over static, fixed-thrust-profile rocket motors. Our design features an all-in-one axial propulsion system with integral thrust vector control, deep throttling and drag reduction. The Active Nozzle Propulsion System applies our controllable solid propulsion technology to the Army’s long-range precision fires modernization priority, enhancing weapon system target acquisition and lethality, in addition to range and maneuverability.

In the Army’s second Expeditionary Technology Search, or xTechSearch 2.0, competition in 2019, we were selected to conduct a proof-of-concept demonstration as one of 12 finalists out of an initial field of 170 entrants. For the demonstration, we developed a prototype and conducted a hot-fire test, which showed the relevance of our Active Nozzle Propulsion System design to Army needs and the efficacy of our technical approach. The results of the test are shown under “Successful Hot Fire Test with Flight Modeling.”

We currently are pursuing opportunities for further development, testing and maturation of this application of our controllable solid propulsion technology.

Application to Army Modernization Priority for Long-range Precision Fires

Our active thruster nozzle design directly responds to the Army’s modernization priority for long-range precision fires that provide long-range and deep-strike capability critical to winning in a fight against a peer adversary. This capability is essential to enabling “multi-domain forces to penetrate and neutralize enemy A2/AD (anti-access/area denial) capabilities while ensuring military overmatch at every echelon,” as stated in the 2019 Army Modernization Strategy.

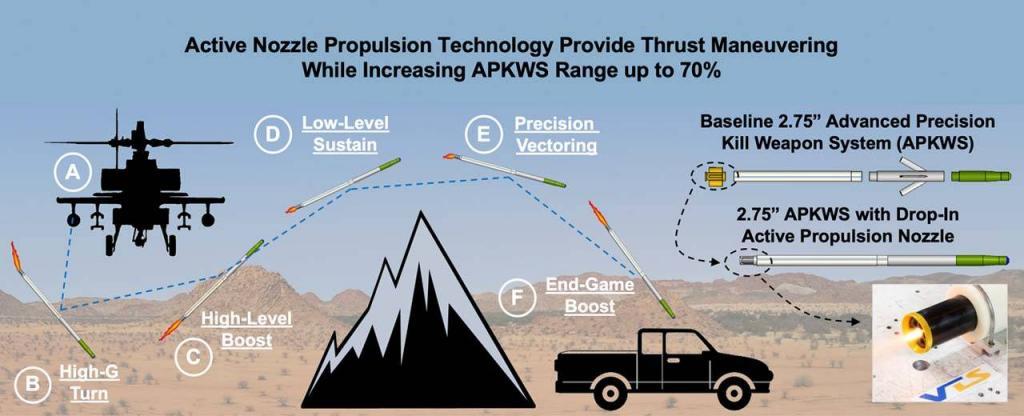

Because we have conceived of our active thruster nozzle design as a screw-in upgrade, it would be applicable to modernizing current weapon systems, as well as to future weapon systems. Our current system design could provide an upgrade capability for the Army’s 2.75-inch Advanced Precision Kill Weapon System (APKWS). Other potential upgrade applications for our active thruster nozzle technology include tactical air-to-air, air-to-surface, surface-to-air and surface-to-surface missiles and the strategic long-range cannon, as well as lower-tier missile defense. In addition, there are potential commercial applications for the technology in the mining and oil and gas industries.

“Smart” Nozzle Increases Range and Precision

Our active thruster nozzle is essentially a “smart” nozzle. Replacing an existing missile or artillery nozzle with our active thruster nozzle would result in a “smart” rocket motor from end to end.

This design increases lethal range by increasing operation time through either continuous thrust throttling with options for extinguishable and reignitable operation. With flexible on-demand thrust amplitude capability, the design enables options for air-to-air, air-to-surface, surface-to-air and surface-to-surface engagements.

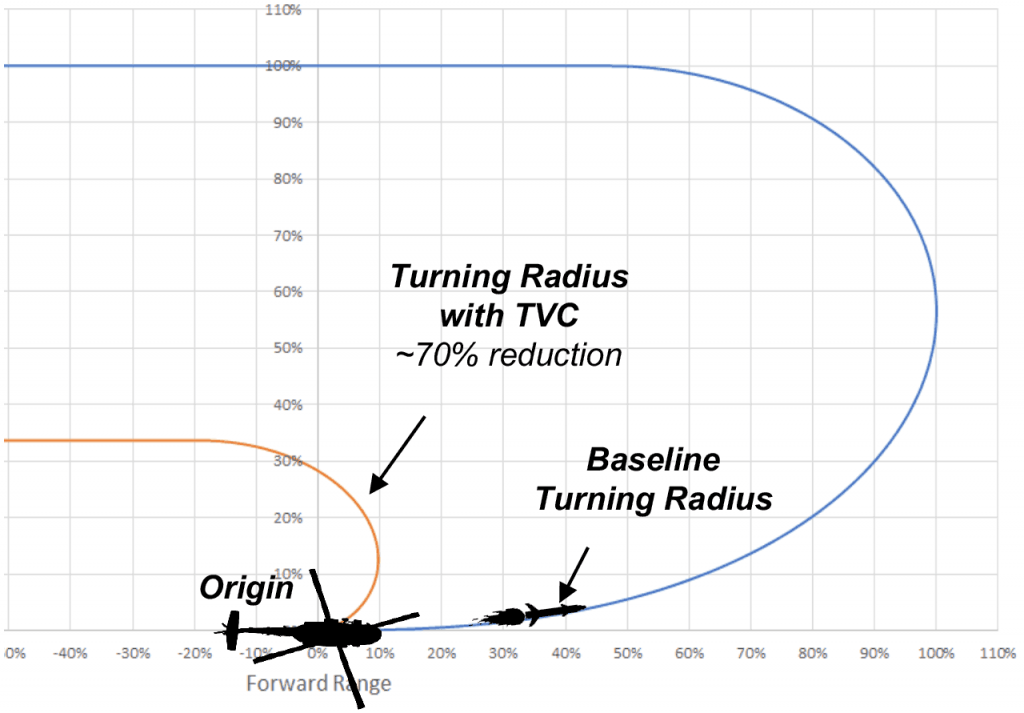

The design improves precision maneuverability by decreasing turning radius through an innovative multi-nozzle operation that simultaneously throttles the axial thrust while steering the missile through attitude control thrust.

Our technical approach employs a portfolio of proprietary hardware, system architectures, innovative low-cost materials and state-of-the-art manufacturing methods. Our technology enables size, weight, power and cost (SWaP-C) solutions to improve overall performance, capability and safety.

The Active Nozzle Propulsion System design includes the following.

- Advanced control algorithms

- Highly accurate proportional thrusters

- Hot-running materials

- Advanced structural insulators

- Thermal coatings

- Wooden round solid propellant with safe handling and storage for warfighters

- Safe, insensitive munitions-compliant ignition systems

Air-to-Surface Engagement Scenario Example

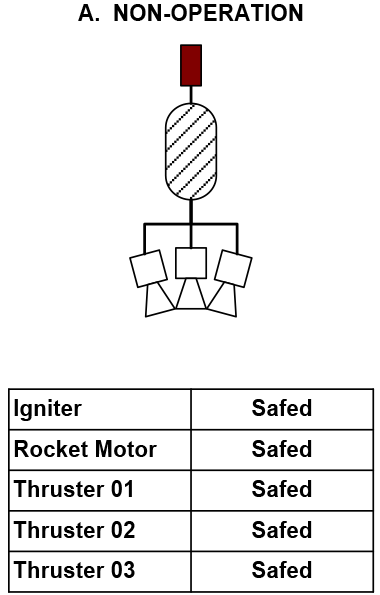

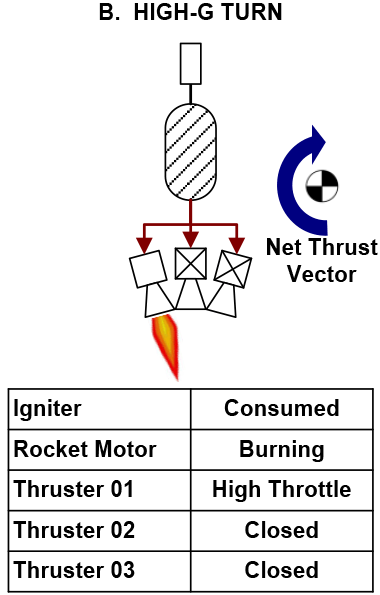

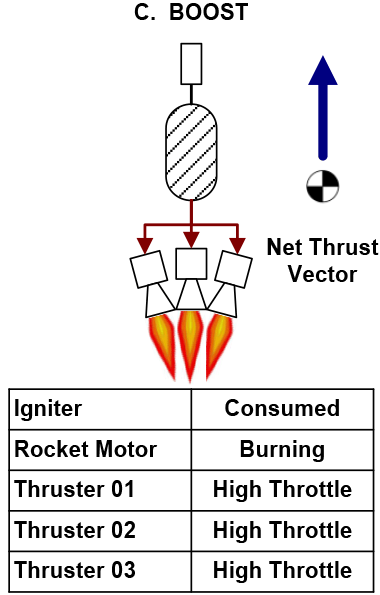

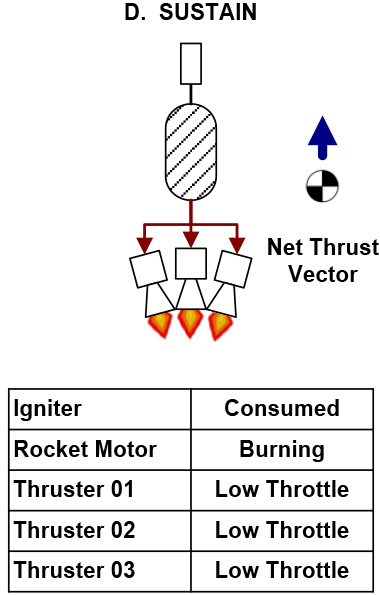

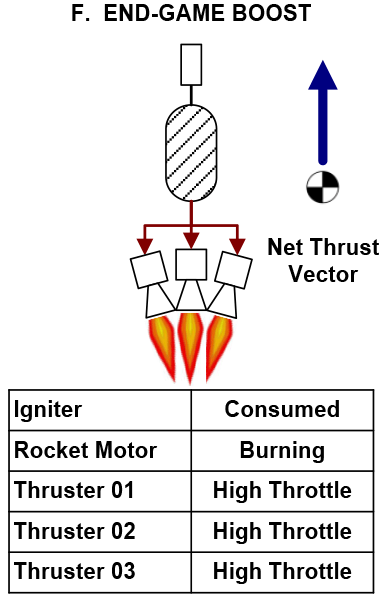

As an example, in an air-to-surface engagement where the ordnance needs to shoot over a hill to hit a distant target, the active thruster nozzle propulsion system would go through this sequence, which also is shown in the following illustrations. This sequence of high-level boost, low-level sustain and precision targeting manages the kinetic energy to extend the engagement range and improve targeting accuracy and lethality.

- A: Non-Operation to Ordnance Initiation – to arm and launch

- B: High-g Turn – to ensure clearance of obstacle

- C: Boost – to achieve peak velocity for ascent

- D: Sustain – to optimize flight and drag profile to increase range

- E: Precision Thrust Vector Control – to precisely steer to the target

- F: End-game Boost – to increase lethality

Operation in Air-to-Surface Engagement

Status of Igniter, Rocket Motor and Thrusters in Air-to-Surface Engagement

Successful Hot Fire Test with Flight Modeling

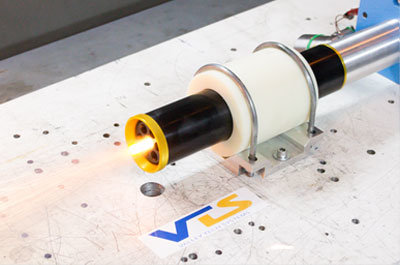

In August 2019, we successfully completed a single-axis hot-fire test of a 2.75” representative thruster nozzle prototype, which mitigated major risks and provided data to anchor performance benefits. This test brought the system to technology readiness level 4 (TRL-4) (component and/or breadboard validation in laboratory environment).

Hot-fire test of Prototype Active Nozzle Propulsion System in August 2019.

Here is a summary of the test results.

- Successful ignition

- Performance within desired prediction bounds

- No jamming, clogging or excessive ablation

- Thermal margin and thermal shock survival demonstrated

- No combustion instability or chugging observed at low pressures

- Ballistics verified

- Thrust calculated for post-test modeling

- Data collected with no anomalous data

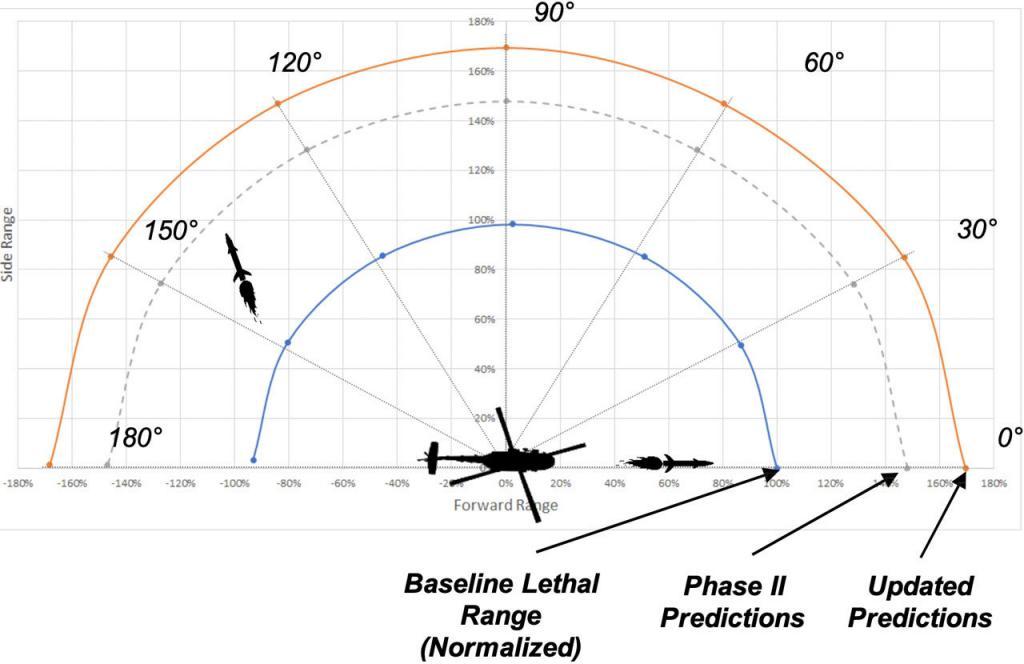

Using hot-fire test data to anchor performance benefits, the flight modeling was updated as follows. Results indicate >70% increase in maneuverability and >67% increase in range. Performance is enabled by thrust vector control, deep throttling, and drag reduction.

Turning Radius Flight Modeling

Lethal Range Flight Modeling

Next Steps

Our proof-of-concept demonstration for xTech Search mitigated many design risks and matured the prototype to TRL-4. By leveraging our accomplishments in controllable solid propulsion technology for other Department of Defense agencies and the support of a commercialization partner, rapid maturation of the Active Nozzle Propulsion System to TRL-9 (actual system proven through successful mission operations) can be achieved to significantly improve the performance, capability and safety of the Army’s current and future long-range precision fires weapons systems.

Acknowledgements and References

Valley Tech Systems acknowledges the U.S. Army organizations that provided insight and support during our participation in the Army’s xTech Search 2.0. This included the following.

- Assistant Secretary of the Army for Acquisition, Logistics and Technology (ASA(ALT)), U.S. Army Research Laboratory

- U.S. Army Combat Capabilities Development Command Armaments Center, Picatinny Arsenal

- U.S. Army Combat Capabilities Development Command Aviation & Missile Center, Redstone Arsenal

The author acknowledges the following individuals for their contributions to the design and testing of the Active Nozzle Propulsion System.

- Allen Yan, who led our participation in xTech Search 2.0 as program manager for the Active Nozzle Propulsion System

- Dustin Barr, operations director, Aerospace Division, Valley Tech Systems

A video of Valley Tech Systems’ proof-of-concept demonstration on Oct. 14, 2019, for the xTechSearch 2.0 competition is available from the U.S. Department of Defense’s Defense Visual Information Distribution Service.