Propulsion Systems

Propulsion Systems

New HeightsOur propulsion systems reach new heights by making solids perform like liquids.

Making Solids Perform Like Liquids

We are setting new standards in solid propulsion. Our technical innovations can deliver precise, long-duration thrust for orienting, positioning and steering missiles or space launch payloads, as well as high levels of thrust for hypersonic applications. Our controllable solid propulsion technology emulates the performance of liquid and cold-gas systems. This enables higher precision, improved reliability, faster response, safer operation and better affordability. Developing this next-gen technology for crucial missions makes Valley Tech Systems an innovative engineering company.

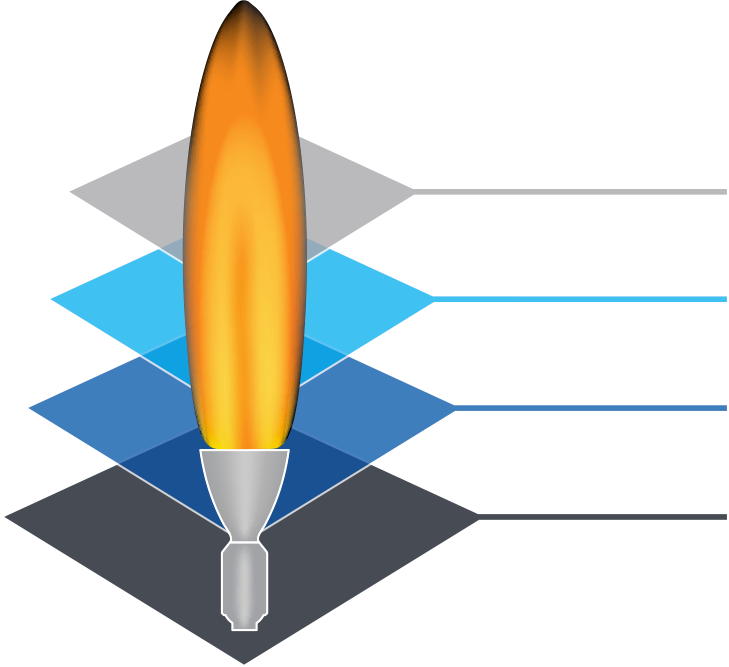

Controllable Solid Propulsion Technology

Here’s how we are advancing controllable solid propulsion.

- Innovative architectures regulate ignition, extinguishment and throttling of solid propellant, plus thermal management. (Patents and patents pending.)

- Proportional thrusters provide a wide range of thrust, on-demand impulse, with 360-degree thrust vector controllability at high frequency response.

- Extinguishment and reignition technology increases operational duration by repeatedly turning the propulsion off and on as needed.

- Components and materials employed include hot-gas valves, gas accumulators, high-temperature-capability refractory metals, high-temperature insulation and proven solid propellant.

Range of Government & Commercial Applications

Our next-gen solid propulsion technology meets requirements for Department of Defense, Department of Energy, NASA and commercial space systems. Our products perform under extreme conditions to substantially enhance performance for applications that include: missile defense interceptors and kill vehicles; strategic, tactical and hypersonic missiles, and reentry systems; and civil, commercial and military space launch systems and payloads.

Our capabilities include:

- Divert, attitude, post-boost and roll control systems

- Thrusters, nozzles and hot-gas valves

- Reaction and roll control systems

Photo: Leah Garton, U.S. Missile Defense Agency

Divert, Attitude, Post-boost & Roll Control Systems

These systems perform a series of precise and well-timed maneuvers to get a missile or interceptor to its target.

- Booster attitude control and post-boost control systems for strategic missiles can steer and orient payloads after launch into space with deep throttling for improved mission flexibility.

- Divert and attitude control systems for missile defense interceptors can steer kill vehicles to their targets with increased operating times over state-of-the art technology.

Thrusters, Nozzles & Hot-gas Valves

These subsystems are the propulsion workhorses that direct energy output to orient, position and steer missiles and payloads.

- Combined duty-cycle thrusters for hypersonic defense and tactical programs can provide rapid-response, high-g-capable, scalable systems.

- Active nozzle propulsion systems for tactical missiles can provide increased long-range precision propulsion and thrust vectoring using low-cost materials at quantities of scale.

Photo: NASA Wallops Flight Facility

Reaction & Roll Control Systems

These systems provide stability by counteracting the tendency of a missile to rotate in three dimensions – pitch, roll and yaw.

- Reaction and roll control systems for affordable launch vehicles can adjust trajectory and control rotation for accurate payload orientation, inertial pointing and deployment.

- Payload deployment accuracy is improved through precision operation with low minimum impulse bit.

Next-gen Vs. Conventional Solid & Liquid Propulsion

Conventional solid propulsion systems burn propellant continuously, impacting how and when the propulsive energy can be used. This diminishes operation time as compared to other types of propulsion systems of the same size and weight. Our next-gen systems don’t have those limitations. We regulate energy output with throttling and cycles of extinguishment and ignition.

Liquid propulsion systems require special precautions for shipping, handling and storing the hypergolic or toxic mono- or bipropellant, pushing up cost. In contrast, our next-gen solid propulsion systems do not require these safety measures, which lowers cost throughout the system’s lifecycle.