Sustained Performance with Significant Safety and Cost Benefits

To enable wider use of solid propellant thrusters for missile and space launch systems, Valley Tech Systems, Inc., has developed a new thruster technology under an Air Force Research Laboratory (AFRL) program. Valley Tech Systems has validated the controllable solid-propulsion thruster design in a hot-fire test at the company’s test facility in Lovelock, Nev. A prototype successfully performed continuously for hundreds of seconds – the longest firing ever of a system of this type.

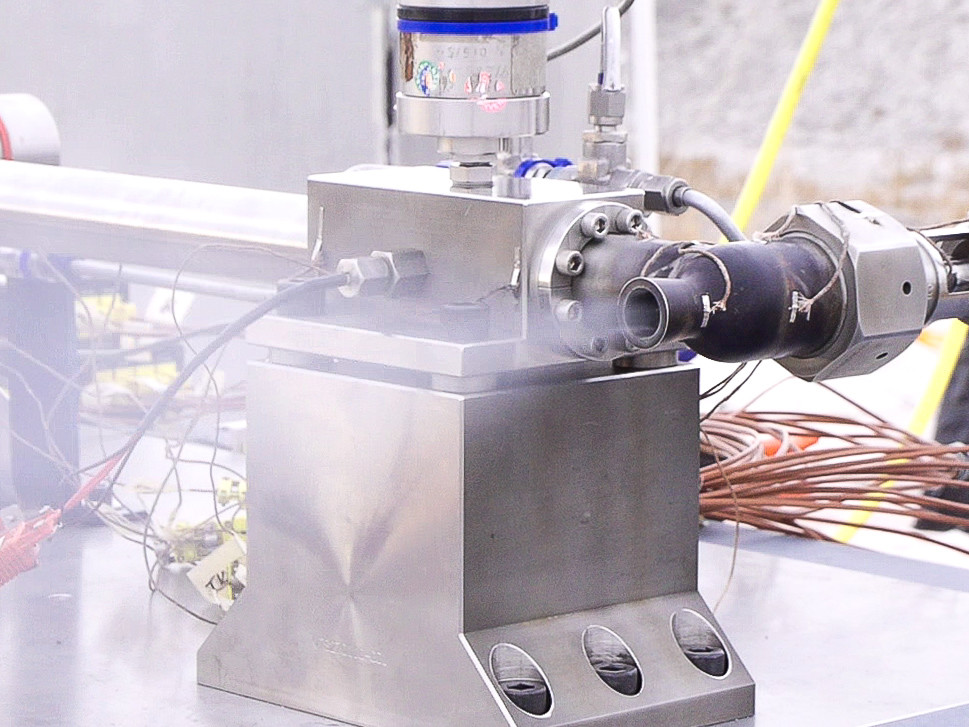

Valley Tech Systems has achieved the longest-duration-to-date operation of a controllable solid-propulsion thruster in a successful hot-fire test for hundreds of seconds in Lovelock, Nev. (Image: Valley Tech Systems, Inc.)

“This breakthrough in long-duration throttling opens the door to the advantages of solid propellant thrusters across a broader spectrum of national security programs, as well as government and commercial space applications,” said Russell Carlson, vice president, Aerospace Division, Valley Tech Systems. “Along with long-duration performance, our design focuses on low lifecycle costs and fielded system safety. Key elements of our approach include advanced high-temperature refractory metals and reusable high-temperature insulation material, combined with a fully DoD-qualified solid propellant manufactured by Nammo, our strategic partner for advanced energetic materials.”

The sustained performance achieved with the company’s long-duration throttling makes solid-propulsion thrusters a safer, more affordable alternative for applications in which liquid-propulsion thrusters currently are used. Storable liquid bi-propellant-fueled systems typically have high lifecycle costs due to their toxicity, whereas the solid fuel used by Valley Tech Systems is less hazardous. The Valley Tech Systems technology regulates the ballistic thrust performance of solid rocket fuel, dramatically boosting its energy efficiency.

AFRL funded development of the long-duration controllable solid-propulsion thruster technology through its Small Business Innovation Research program for the development of advanced technologies for post boost propulsion systems, which steer and orient payloads after they are launched into space. The technology also can be applied to booster reaction control systems for the launch of small satellites.

Valley Tech Systems, Inc., is an aerospace engineering company that specializes in innovative rocket propulsion systems and command, control, communications, computers, intelligence, surveillance and reconnaissance (C4ISR) systems and services. The privately held company has its headquarters in Folsom, Calif., and its propulsion development facility in Reno, Nev.

Distribution Statement A: Approved for Public Release; Distribution Is Unlimited. AFRL PA# 18221